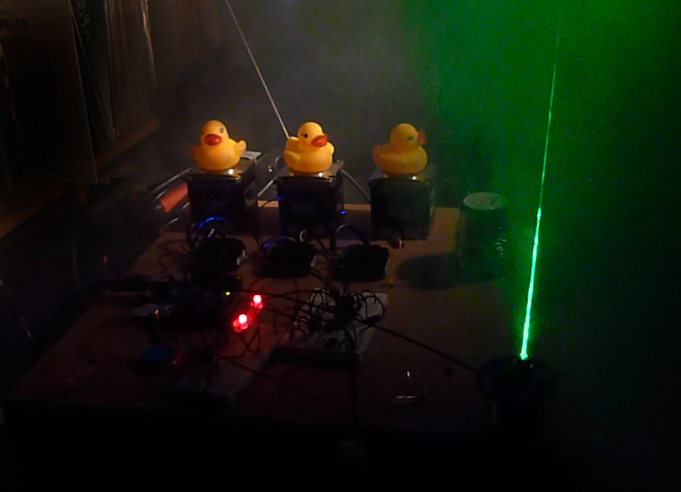

The Rave Kestrel - some more photos

Thanks to:

Gary from Zapp Automation for the advice on stepper motor drivers

Patrick Furness for use of camera and lights

Paddy and Charlie for use of their warehouse space

Philip for code advice

Rachel & family for a useful deadline and great NYE party

Monkeytown Music / BPitch Control for authorising the use of "Kill Bill Vol 4" by Modeselektor

A while after choosing that track, I realised that, incredibly, Modeselektor is in fact an anagram of "Mode O'Kestrel"!